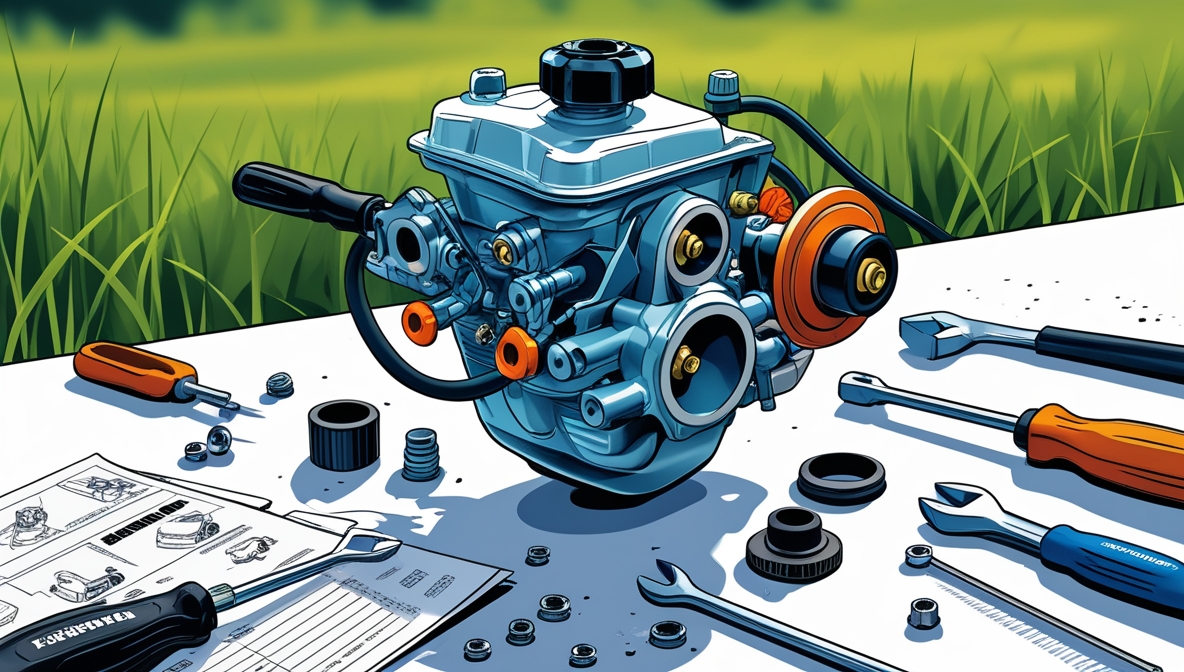

A malfunctioning carburetor can render your lawnmower useless, leaving you with an overgrown lawn. Fortunately, repairing a lawn mower carburetor is often a manageable DIY task, saving you the cost of professional repair or a new mower. This beginner’s guide will walk you through the process step-by-step, providing clear instructions and helpful tips to get your mower running smoothly again. Remember to always prioritize safety and consult your lawnmower’s manual for specific instructions and diagrams.

Contents

- Assessing Your Lawn Mower’s Carburetor

- Gathering Necessary Tools and Parts

- Disassembling the Carburetor Carefully

- Cleaning the Carburetor Thoroughly

- Inspecting for Damaged Components

- Replacing Worn or Damaged Parts

- Reassembling the Carburetor Properly

- Adjusting the Carburetor Settings

- Testing the Repaired Carburetor

- Troubleshooting and Further Steps

Assessing Your Lawn Mower’s Carburetor

Before you begin any repairs, it’s crucial to accurately diagnose the problem. A faulty carburetor often manifests as difficulty starting, sputtering, stalling, or running poorly at various speeds. Listen carefully to the engine’s sound; a sputtering or erratic sound points towards a fuel delivery issue, likely originating in the carburetor. Furthermore, check the spark plug to ensure it’s functioning correctly. A faulty spark plug can mimic carburetor problems, leading to misdiagnosis.

Inspect the fuel lines for any cracks, leaks, or blockages. Ensure the fuel tank is properly filled with fresh, clean fuel. Old, stale fuel can gum up the carburetor and cause performance issues. If you’ve already checked these things and the problem persists, it’s highly likely your carburetor needs attention. Remember to always disconnect the spark plug before starting any work on the carburetor to prevent accidental starting.

Gathering Necessary Tools and Parts

To successfully repair your lawn mower carburetor, you’ll need a selection of tools and potentially some replacement parts. Essential tools include a Phillips head screwdriver, a flathead screwdriver, a carburetor cleaning kit (containing brushes, cleaning needles, and compressed air), adjustable wrenches, pliers, and a container for cleaning parts. You’ll also need rags or paper towels for cleaning and a bowl of carburetor cleaner. Safety glasses and gloves are crucial for protecting yourself from solvents and sharp parts.

Crucially, you might need replacement parts. Commonly replaced parts include gaskets, jets, diaphragms, and O-rings. These small components often deteriorate over time and cause leaks or blockages. It’s advisable to order these parts beforehand, referencing your lawn mower’s model number to ensure compatibility. Having these parts on hand will streamline the repair process and prevent delays.

Disassembling the Carburetor Carefully

Now, carefully disassemble the carburetor. Start by disconnecting the fuel lines and the throttle cable. Take photos or make detailed notes as you proceed, documenting the position of each part. This will be invaluable during reassembly. Use the appropriate screwdrivers to remove screws and bolts, ensuring you don’t strip the heads. Work methodically, removing one component at a time and placing it in an organized manner to avoid losing small parts.

Gently remove the carburetor bowl and carefully clean any debris or sediment that accumulates at the bottom. Pay close attention to the float and needle valve, ensuring they move freely. A stuck float can lead to flooding, while a faulty needle valve can cause fuel leaks. Remember to handle all parts with care, as they are often delicate and easily damaged.

Cleaning the Carburetor Thoroughly

Once disassembled, thoroughly clean every component of the carburetor. Use the carburetor cleaning kit to carefully clean all passages and jets. Compressed air can help dislodge stubborn debris. Soak the parts in carburetor cleaner, following the manufacturer’s instructions. This will dissolve any gumming or varnish that may be obstructing fuel flow. Allow the parts to soak for the recommended time, then scrub them gently with the brushes provided in the kit.

After soaking and scrubbing, rinse the parts thoroughly with clean solvent or compressed air to remove any residual cleaner. Pay particular attention to the jets, as even small blockages can significantly impact performance. Inspect each part carefully for any signs of damage or wear. Thorough cleaning is crucial for restoring the carburetor’s proper function.

Inspecting for Damaged Components

After cleaning, carefully inspect all components for any signs of wear or damage. Look for cracks, tears, or holes in diaphragms, gaskets, or O-rings. Check for any bent or broken parts. Pay close attention to the float, ensuring it moves freely and doesn’t stick. A damaged float can cause the carburetor to flood, leading to engine problems. Similarly, inspect the needle valve for any wear or damage that might prevent it from sealing properly.

If you find any damaged components, replace them immediately. Using worn or damaged parts will only lead to further problems down the line. Remember that even small imperfections can significantly impact the carburetor’s performance. Replacing these parts is relatively inexpensive and will significantly increase the likelihood of a successful repair.

Replacing Worn or Damaged Parts

Replacing worn or damaged parts is a straightforward process. Start by installing new gaskets and O-rings. These ensure a proper seal and prevent fuel leaks. Carefully align and install the new diaphragms, ensuring they fit snugly and are not stretched or damaged during installation. When replacing jets, ensure they are correctly sized and installed according to the manufacturer’s specifications. Using the wrong size jets can significantly affect the engine’s performance.

Remember to refer to your lawnmower’s manual or a detailed diagram for guidance. If you’re unsure about the correct orientation or placement of a part, consult online resources or contact a small engine repair specialist. Take your time and work methodically to ensure everything is installed correctly.

Reassembling the Carburetor Properly

Now, carefully reassemble the carburetor, following the reverse order of disassembly. Refer to your photos or notes to ensure you place each part in its correct position. Use the appropriate screws and bolts, tightening them to the correct torque specification. Ensure all gaskets and O-rings are properly seated to prevent leaks. Carefully reconnect the fuel lines and throttle cable, ensuring they are securely attached.

Before installing the carburetor back onto the engine, double-check everything. Make sure all screws are tightened and all parts are correctly positioned. A single misplaced part can lead to significant problems. Take your time and carefully review your work before moving on to the next step.

Adjusting the Carburetor Settings

Once reassembled, you may need to adjust the carburetor settings. These settings control the fuel-to-air mixture, affecting the engine’s performance. The specific adjustments vary depending on the carburetor model. Consult your lawnmower’s manual for detailed instructions on adjusting the idle speed screw, the high-speed needle, and the low-speed needle. These adjustments are usually made using small screwdrivers.

Start by adjusting the idle speed screw to ensure the engine idles smoothly. Then, adjust the high-speed needle to optimize performance at higher engine speeds. Finally, adjust the low-speed needle to fine-tune the engine’s performance at lower speeds. Small adjustments can make a big difference, so make incremental changes and test the engine’s performance after each adjustment.

Testing the Repaired Carburetor

After reassembly and adjustment, it’s time to test the repaired carburetor. Reconnect the spark plug, ensuring it’s securely fastened. Add fresh fuel to the tank. Carefully start the lawnmower and observe its performance. Listen for any unusual sounds, such as sputtering or backfiring. Check for any fuel leaks. If the engine runs smoothly at various speeds, your repair was successful.

If the engine still runs poorly, you may need to re-check your work or consult a small engine repair specialist. Troubleshooting might involve re-examining the carburetor’s adjustments, ensuring all connections are secure, or checking for other potential issues in the fuel system. Remember, patience and persistence are crucial in repairing a lawn mower carburetor.

Troubleshooting and Further Steps

If your lawnmower still doesn’t run properly after following these steps, several further steps can be taken. Firstly, double-check all connections and ensure there are no leaks in the fuel lines. Secondly, inspect the air filter; a clogged air filter can restrict airflow and affect engine performance. Thirdly, consider the possibility of other engine problems, such as a faulty spark plug or ignition coil.

If you’ve exhausted all troubleshooting options, it might be time to seek professional help. A small engine repair specialist has the expertise and tools to diagnose and repair more complex issues. They can also provide guidance on maintaining your lawnmower to prevent future carburetor problems. Remember, attempting repairs beyond your skill level can cause further damage.

Repairing a lawn mower carburetor can be a rewarding DIY project, saving you time and money. By following these steps carefully and taking your time, you can successfully restore your lawnmower to its optimal performance. Remember safety first, and don’t hesitate to seek professional help if you encounter difficulties. Regular maintenance, such as using fresh fuel and cleaning the air filter, can help prevent future carburetor problems and keep your lawnmower running smoothly for years to come.