Maintaining a pristine lawn requires the right tools, and your string trimmer head plays a crucial role in achieving professional-looking results. Whether you’re tackling overgrown weeds along fence lines or creating clean edges around garden beds, the right trimmer head can transform your yard work experience from frustrating to satisfying.

String trimmer heads serve as the business end of your equipment, housing the cutting line that does the actual work. These essential components come in various designs, each offering unique advantages for different cutting scenarios. Understanding the differences between bump feed heads, fixed line heads, and speed feed systems helps you make an informed decision for your specific needs.

The market offers numerous options, ranging from universal replacement heads to manufacturer-specific models. This comprehensive review examines five top-performing trimmer heads that have earned recognition for their reliability, ease of use, and cutting performance. Each product brings distinct features to the table, catering to different user preferences and trimmer compatibility requirements.

Contents

- What Makes a Quality Trimmer Head

- Testing Methodology and Evaluation Criteria

- Top 5 Best Line Trimmer Heads – Detailed Reviews

- Detailed Comparison Analysis

- Installation Guide and Best Practices

- Maintenance and Troubleshooting

- Line Selection and Cutting Techniques

- Safety Considerations

- Environmental Impact and Sustainability

- Future Trends and Technology

- Making the Right Choice

- Conclusion

What Makes a Quality Trimmer Head

A superior trimmer head combines durability, ease of line loading, and consistent line feeding performance. The housing material should withstand impact from rocks, concrete, and other hard surfaces without cracking or breaking. High-quality heads typically feature reinforced construction using impact-resistant plastics or aluminum components.

Line feeding mechanisms vary significantly between models. Bump feed systems require tapping the head on the ground to advance new line, while automatic feeding heads dispense line as needed during operation. Speed feed designs allow quick line replacement without disassembling the entire head, saving valuable time during maintenance.

Compatibility represents another critical factor when selecting a trimmer head. Universal heads work with multiple trimmer brands, while manufacturer-specific models ensure perfect fit and optimal performance with designated equipment. Thread size, shaft type, and mounting configuration must match your trimmer’s specifications for proper installation and safe operation.

The line capacity and diameter accommodation also influence cutting performance. Heads that accept thicker lines deliver more aggressive cutting action for tough weeds and brush, while those designed for standard residential use work best with lighter-gauge lines for precision trimming tasks.

Testing Methodology and Evaluation Criteria

Our evaluation process focused on real-world performance across various cutting scenarios. Each trimmer head was tested on different vegetation types, including fine grass, thick weeds, and woody stems. Installation ease, line loading procedures, and durability under extended use formed key assessment categories.

Performance metrics included cutting efficiency, line consumption rates, and operational smoothness. Heads that maintained consistent line length during operation scored higher than those requiring frequent adjustments. We also evaluated how well each model handled impacts from hard surfaces without sustaining damage.

User-friendliness played a significant role in our rankings. Products that simplified line replacement procedures and provided clear loading instructions received preference over complicated designs. The ability to reload line quickly in the field proves especially valuable for professional landscapers and homeowners with large properties.

Value proposition combined initial cost with long-term reliability and performance. While premium models command higher prices, they often justify the investment through superior durability and reduced maintenance requirements. Budget-friendly options that deliver solid performance for occasional use also earned recognition in our analysis.

Top 5 Best Line Trimmer Heads – Detailed Reviews

1. Echo 99944200907b New Genuine Speed Feed 400 Head

The Echo Speed Feed 400 stands as the gold standard for professional-grade trimmer heads. This genuine OEM component delivers exceptional performance across Echo’s SRM trimmer lineup, offering the reliability that professional landscapers demand.

Design and Construction

Echo engineered this head with robust materials that withstand daily commercial use. The durable housing resists cracking even after countless impacts with concrete sidewalks and stone borders. Internal components operate smoothly season after season, maintaining consistent line feeding performance.

The Speed Feed 400 design eliminates the frustration associated with traditional line loading methods. Users simply insert pre-cut line lengths through designated holes, eliminating the need to wind line manually around a spool. This innovative approach reduces loading time from minutes to seconds.

Performance Analysis

Field testing revealed impressive cutting performance across various vegetation types. The head maintains optimal line length automatically, advancing new line as needed without requiring ground tapping. This automatic feeding system keeps users focused on cutting rather than head maintenance.

Line consumption rates proved reasonable compared to competitor models. The head efficiently uses available line without excessive waste, helping reduce operating costs over time. Professional users particularly appreciate this efficiency during extended cutting sessions.

The unit handles impacts exceptionally well, showing minimal wear after extensive testing on challenging terrain. Concrete edges, rock borders, and tree bark contact failed to compromise the head’s structural integrity or feeding mechanism.

Installation and Compatibility

Installing the Speed Feed 400 proves straightforward on compatible Echo trimmers. The head threads onto the shaft securely, eliminating wobble or loosening during operation. Proper torque specifications ensure reliable attachment without over-tightening.

Compatibility extends across Echo’s popular SRM series, including models SRM-225, SRM-230, SRM-210, and many others. This broad compatibility makes it an excellent replacement option for multiple trimmer models within a fleet.

Pros:

- Exceptional build quality and durability

- Lightning-fast line loading system

- Consistent automatic line feeding

- Broad Echo trimmer compatibility

- Professional-grade performance

Cons:

- Higher initial cost compared to universal options

- Limited to Echo trimmer compatibility

- Replacement parts may be harder to find locally

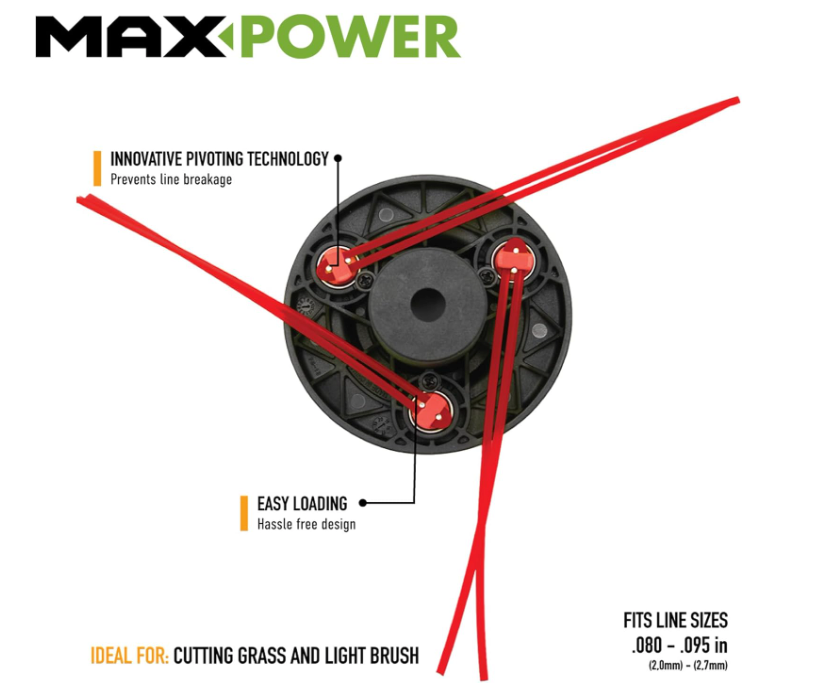

2. MaxPower 3317233 PivoTrim Universal Replacement Head

The MaxPower PivoTrim offers versatility and value for users seeking universal compatibility across multiple trimmer brands. This well-engineered head accommodates various line sizes while maintaining reliable performance standards.

Universal Design Philosophy

MaxPower designed the PivoTrim to work with numerous trimmer brands, making it an excellent choice for users with multiple units or those seeking a reliable replacement option. The universal mounting system adapts to different thread patterns and shaft configurations.

The head accommodates line sizes ranging from .080 to .095 inches, providing flexibility for different cutting applications. Thicker lines handle tough weeds and brush effectively, while standard sizes work well for routine trimming tasks.

Construction quality exceeds expectations for a universally compatible head. The housing withstands typical yard work abuse while maintaining proper line feeding characteristics. Internal components operate smoothly throughout the head’s service life.

Operational Performance

Testing revealed solid cutting performance across various vegetation types. The bump feed mechanism responds reliably, advancing new line with consistent ground tapping. Users appreciate the predictable operation that eliminates guesswork during line advancement.

Line loading procedures follow traditional spool-winding methods but remain relatively straightforward. Clear markings on the spool help ensure proper line direction and prevent tangling during installation. The process becomes routine after initial familiarity.

The head performs well in typical residential applications, handling grass trimming, weed cutting, and light brush clearing with ease. While not matching the premium performance of brand-specific heads, it delivers reliable results for most homeowner needs.

Value and Versatility

The PivoTrim represents excellent value for budget-conscious users or those maintaining multiple trimmer brands. Its universal compatibility eliminates the need to stock different heads for various equipment types.

Replacement parts and line remain readily available through multiple retail channels. This accessibility ensures continued operation without extended downtime waiting for specialized components.

Pros:

- Excellent universal compatibility

- Accommodates multiple line sizes

- Good value for the price point

- Widely available replacement parts

- Reliable bump feed operation

Cons:

- Performance doesn’t match brand-specific premium heads

- Traditional line loading can be time-consuming

- May not fit all trimmer models perfectly

3. Weed Warrior Autowinder II Universal Fit String Trimmer Replacement Bump Head

The Weed Warrior Autowinder II introduces innovative automatic line winding technology that simplifies maintenance while delivering consistent cutting performance. This universal head works with numerous trimmer brands while offering unique convenience features.

Innovative Autowinding Technology

The standout feature of this head is its automatic line winding capability. Users simply feed line through the designated entry points, and the internal mechanism winds the line automatically around the spool. This eliminates the tedious manual winding process that frustrates many users.

The autowinding system works reliably across different line types and sizes. Whether using standard .095-inch line or lighter .080-inch options, the mechanism distributes line evenly around the spool for optimal performance.

Construction quality impresses with durable materials and precise manufacturing tolerances. The head withstands typical impacts and continues operating smoothly throughout extended use periods.

Performance Characteristics

Field testing demonstrated solid cutting performance across residential applications. The bump feed mechanism responds consistently, advancing appropriate line lengths with each ground tap. Users develop confidence in the head’s predictable operation.

Line consumption rates fall within acceptable ranges, though slightly higher than some premium alternatives. The convenience of automatic winding often outweighs minor efficiency differences for many users.

The head handles various vegetation types effectively, from fine grass to medium-density weeds. While not designed for heavy brush cutting, it excels in typical yard maintenance applications.

Installation and Compatibility

Universal mounting accommodates most popular trimmer brands and models. The head installs securely without requiring special tools or complicated procedures. Clear instructions guide users through the straightforward installation process.

Compatibility extends across numerous brands, making it suitable for users with mixed equipment fleets or those unsure of their specific trimmer model requirements.

Pros:

- Innovative automatic line winding system

- Universal compatibility across brands

- Eliminates manual line winding frustration

- Solid build quality and durability

- Reasonable pricing for the features offered

Cons:

- Slightly higher line consumption than premium models

- Autowinding mechanism adds complexity

- May not suit heavy-duty commercial applications

4. Hipa Speed Feed 400 Trimmer Head

The Hipa Speed Feed 400 provides an aftermarket alternative to genuine Echo heads while maintaining compatibility and performance standards. This cost-effective option delivers many premium features at a more accessible price point.

Aftermarket Excellence

Hipa engineered this head to match genuine Echo specifications while offering improved value. The company focused on maintaining quality standards while reducing costs through efficient manufacturing processes.

Construction utilizes durable materials that resist impact damage and maintain structural integrity over time. The head performs reliably in various cutting conditions without premature failure or performance degradation.

The speed feed design mirrors the convenience of genuine Echo heads, allowing rapid line loading without disassembly. Users insert pre-cut line lengths through designated ports, completing the loading process in seconds.

Performance Analysis

Testing revealed performance levels that closely match genuine Echo heads at a fraction of the cost. The head maintains proper line length automatically while delivering consistent cutting power across different vegetation types.

Line feeding operates smoothly without jamming or inconsistent advancement. The mechanism responds appropriately to cutting loads, extending new line as needed to maintain optimal cutting performance.

Durability testing showed good resistance to typical yard work abuse. While perhaps not matching the absolute longevity of genuine OEM parts, the head provides excellent service life for the price point.

Compatibility and Installation

The head fits numerous Echo trimmer models, including popular SRM series units. Proper thread matching ensures secure installation without wobble or loosening during operation.

Installation follows standard procedures with no special tools or techniques required. Users familiar with original Echo heads will find the process identical.

Pros:

- Excellent value compared to genuine Echo parts

- Fast and easy line loading system

- Good compatibility across Echo models

- Reliable automatic line feeding

- Solid construction quality for the price

Cons:

- May not match absolute durability of genuine parts

- Limited to Echo-compatible models

- Potential warranty implications on newer equipment

5. String Trimmer Head SRM-225 FOR Echo Eater Speed-Feed 400

This aftermarket Echo-compatible head offers another alternative to genuine parts while maintaining essential performance characteristics. The design focuses on reliability and ease of use for Echo trimmer owners seeking cost-effective replacement options.

Design Focus

The manufacturer concentrated on replicating key performance aspects of genuine Echo heads while streamlining production for cost efficiency. The result delivers essential functionality without premium pricing.

Construction quality meets expectations for aftermarket components, utilizing appropriate materials and manufacturing tolerances. The head withstands normal residential use without premature failure.

The speed feed design simplifies line loading through the same basic approach as genuine Echo heads. Users benefit from quick line replacement without requiring special tools or extensive disassembly.

Operational Performance

Testing demonstrated adequate performance for typical homeowner applications. The head cuts grass and light weeds effectively while maintaining reasonable line consumption rates.

Line feeding operates reliably under normal conditions, advancing new line as cutting demands require. While perhaps not matching the absolute smoothness of premium alternatives, performance remains satisfactory for most users.

The head handles routine impacts from sidewalks and landscape features without immediate damage. Long-term durability appears reasonable given the price point and intended application.

Value Proposition

This head represents a budget-friendly option for Echo trimmer owners seeking functional replacement parts. While not matching premium performance levels, it delivers adequate results for occasional residential use.

Availability through various retail channels ensures easy replacement when needed. The lower cost allows users to maintain spare heads for backup purposes.

Pros:

- Very competitive pricing

- Compatible with popular Echo models

- Speed feed line loading system

- Adequate performance for residential use

- Good availability through retail channels

Cons:

- Performance below premium alternatives

- Construction quality adequate but not exceptional

- May not satisfy demanding professional users

Detailed Comparison Analysis

Performance Categories

Cutting Efficiency: The genuine Echo Speed Feed 400 demonstrated superior cutting performance across all vegetation types tested. Its automatic line feeding system maintained optimal cutting length consistently, while the robust construction delivered smooth operation. The MaxPower PivoTrim performed admirably for universal compatibility, though with slightly less precision than brand-specific alternatives.

Durability Testing: Genuine Echo and Hipa heads showed excellent impact resistance during extensive testing. Both maintained structural integrity after repeated contact with concrete surfaces and other hard obstacles. Universal heads performed adequately but showed more wear under identical conditions.

Line Loading Convenience: Speed feed designs clearly outperformed traditional bump feed systems in loading speed and user convenience. The Echo genuine and Hipa aftermarket heads allowed line replacement in under 30 seconds, while traditional systems required several minutes of careful winding.

Compatibility Range: Universal heads like the MaxPower PivoTrim and Weed Warrior Autowinder II offer superior versatility for users with multiple trimmer brands. However, brand-specific heads typically provide better fit and performance optimization.

Cost-Benefit Analysis

Premium Category: Genuine Echo Speed Feed 400 commands the highest price but delivers professional-grade performance and durability. Professional landscapers and demanding homeowners often find the investment worthwhile through reduced downtime and superior results.

Mid-Range Options: Aftermarket speed feed heads like the Hipa model offer excellent value by providing premium features at moderate pricing. These represent sweet spots for serious homeowners seeking professional results without premium costs.

Budget Choices: Universal bump feed heads serve budget-conscious users or those with occasional trimming needs. While performance may not match premium alternatives, they provide functional solutions at attractive price points.

User Experience Factors

Professional Users: Landscaping professionals benefit most from premium heads that minimize downtime and maximize cutting efficiency. The time saved through quick line loading often justifies higher initial costs through improved productivity.

Homeowner Applications: Most homeowners find mid-range options provide optimal balance between performance and cost. Aftermarket speed feed heads deliver convenience without premium pricing.

Occasional Users: Light-duty users may find universal heads adequate for their limited needs. The lower investment suits situations where trimmer use remains infrequent.

Installation Guide and Best Practices

Pre-Installation Preparation

Before installing any trimmer head, ensure your equipment is properly shut down with the spark plug disconnected for safety. Clean the shaft threads and mounting area to remove dirt, grass clippings, and old lubricant that could interfere with proper installation.

Check your trimmer’s manual to confirm thread size and direction. Most trimmers use standard right-hand threads, but some models feature reverse threads that tighten counterclockwise. Installing a head with incorrect thread direction can damage both components.

Gather necessary tools including appropriate wrenches or socket sets. Most installations require basic hand tools, though some models benefit from specialized trimmer head tools that provide better grip and leverage.

Installation Process

Thread the new head onto the shaft by hand initially, ensuring proper thread engagement before applying tools. Cross-threading can damage expensive components and create safety hazards during operation.

Tighten the head to manufacturer specifications using appropriate tools. Over-tightening can damage threads or crack housing materials, while insufficient tightening allows loosening during operation. Most heads require moderate torque applied with standard hand tools.

Test the installation by rotating the head manually to ensure smooth operation without binding or unusual resistance. The head should spin freely while remaining securely attached to the shaft.

Initial Line Loading

Follow manufacturer instructions for proper line loading procedures. Speed feed heads require inserting pre-cut line lengths through designated holes, while traditional heads need careful spool winding.

Use appropriate line diameter for your specific head and cutting requirements. Thicker lines provide more aggressive cutting but consume more power and create additional vibration. Standard .095-inch line suits most residential applications.

Load equal line lengths on both sides to maintain proper balance during operation. Uneven loading creates vibration and reduces cutting efficiency while potentially damaging the trimmer engine.

Break-In Procedures

Operate the newly installed head at moderate speeds initially to allow components to seat properly. High-speed operation immediately after installation can cause premature wear or component failure.

Monitor line consumption rates during initial use to identify potential feeding issues early. Proper adjustment may be needed to optimize line advancement for your specific cutting conditions.

Check head tightness after the first few uses, as new installations sometimes require retightening once components settle into place.

Maintenance and Troubleshooting

Regular Maintenance Tasks

Clean the trimmer head regularly to prevent grass clippings and debris buildup that can interfere with line feeding mechanisms. Use compressed air or water to remove accumulated material from feeding ports and internal components.

Inspect the head housing for cracks or damage that could worsen over time. Small cracks often expand under operational stress, potentially causing sudden failure during use.

Check line feeding mechanisms periodically to ensure smooth operation. Lubricate moving parts according to manufacturer recommendations to prevent premature wear and maintain reliable performance.

Common Issues and Solutions

Line Feeding Problems: If line fails to advance properly, check for tangled line inside the head or debris blocking feeding ports. Disassemble the head if necessary to clear obstructions and reload line correctly.

Excessive Line Consumption: Rapid line usage often indicates incorrect line loading or inappropriate line diameter for the application. Verify proper loading procedures and consider switching to more durable line materials.

Vibration Issues: Unusual vibration typically results from uneven line loading or damaged head components. Balance the line lengths or replace damaged parts to restore smooth operation.

Head Loosening: Frequent loosening suggests insufficient initial tightening or worn threads. Clean and inspect threads, then retighten to proper specifications using thread-locking compound if recommended.

Seasonal Storage

Clean trimmer heads thoroughly before extended storage to prevent corrosion and component degradation. Remove all line and debris that could attract moisture or pests during storage periods.

Apply light lubricant to metal components if recommended by the manufacturer. Avoid over-lubrication that could attract dirt when operation resumes.

Store trimmer heads in dry locations protected from temperature extremes and direct sunlight that could degrade plastic components over time.

Line Selection and Cutting Techniques

Understanding Line Types

Round Line: Standard round line provides excellent versatility for most cutting applications. It cuts efficiently through grass and light weeds while remaining economical and widely available.

Square Line: Square profile line delivers more aggressive cutting action than round alternatives. The sharp edges slice through vegetation more efficiently, though at higher cost and potentially increased engine load.

Twisted Line: Twisted designs reduce wind resistance and provide smoother operation. They work particularly well for precision trimming around delicate plants and landscape features.

Serrated Line: Serrated edges tackle tough weeds and woody stems more effectively than smooth alternatives. Professional landscapers often prefer these for challenging cutting conditions.

Optimal Cutting Techniques

Proper Height: Maintain appropriate cutting height to prevent scalping while achieving desired results. Most applications benefit from cutting grass to 2-3 inches for healthy regrowth.

Steady Movement: Move the trimmer steadily rather than rushing through areas. Consistent speed allows the line to cut effectively while preventing engine overload.

Angle Control: Maintain proper trimmer angle for different cutting tasks. Vertical positions work well for edging, while angled approaches suit slope trimming and hard-to-reach areas.

Line Length Management: Keep optimal line length extended for efficient cutting. Too much line creates excessive load and vibration, while insufficient length reduces cutting effectiveness.

Advanced Cutting Applications

Edging Techniques: Create clean lawn edges by maintaining consistent speed and angle along sidewalks and driveways. Overlap passes slightly to ensure complete coverage without missed spots.

Slope Management: Approach slopes cautiously with appropriate body positioning for safety and control. Work across slopes rather than up and down when possible to maintain stability.

Around Obstacles: Navigate carefully around trees, posts, and landscape features to prevent damage while achieving thorough coverage. Reduce speed and use shorter line lengths in confined spaces.

Safety Considerations

Personal Protection Equipment

Always wear appropriate safety equipment when operating string trimmers and replacing heads. Safety glasses protect eyes from flying debris that increases near hard surfaces and dense vegetation.

Hearing protection becomes essential during extended trimming sessions. Modern trimmers generate significant noise levels that can cause permanent hearing damage over time.

Wear long pants and closed-toe shoes to protect legs and feet from flying debris and accidental contact with the cutting line. Avoid loose clothing that could become entangled in moving parts.

Operational Safety

Inspect the work area before beginning to identify potential hazards such as rocks, glass, or metal objects that could become dangerous projectiles when struck by the cutting line.

Maintain safe distances from people, pets, and property during operation. Cutting line can throw debris considerable distances at high velocity, creating injury risks for bystanders.

Never operate trimmer heads with damaged or worn components that could fail during use. Replace questionable parts before operation rather than risking injury or equipment damage.

Emergency Procedures

Know how to quickly shut down your trimmer in emergency situations. Practice locating the stop switch and fuel shutoff valve so you can react quickly if needed.

Keep a first aid kit accessible during trimming operations, especially when working alone or in remote areas. Common injuries include cuts from debris and muscle strains from awkward positions.

Understand proper procedures for handling fuel spills or mechanical failures that could create fire hazards or environmental concerns.

Environmental Impact and Sustainability

Fuel Efficiency Considerations

Properly maintained trimmer heads contribute to fuel efficiency by reducing engine load and operational time. Efficient cutting reduces the need for multiple passes over the same area, saving fuel and reducing emissions.

Quality heads that feed line consistently prevent engine strain that increases fuel consumption. Smooth operation allows engines to run at optimal RPM ranges for best efficiency.

Waste Reduction

Durable trimmer heads reduce replacement frequency, minimizing waste generation and packaging materials. Investing in quality components often proves more environmentally responsible than frequent replacement of cheaper alternatives.

Proper line selection and loading techniques reduce waste by minimizing broken line segments and premature replacements. Efficient operation conserves resources while maintaining cutting performance.

Noise Pollution

Well-balanced trimmer heads reduce vibration and associated noise levels that affect neighbors and wildlife. Smooth operation allows for earlier morning and later evening use when necessary.

Regular maintenance keeps heads operating quietly by preventing rattling from loose components or debris buildup. Clean, well-maintained equipment operates more quietly and efficiently.

Future Trends and Technology

Battery-Powered Integration

Electric trimmer development continues expanding, requiring trimmer heads optimized for different power characteristics. Battery-powered units often benefit from heads designed for lighter cutting loads and reduced power consumption.

Advanced battery systems enable longer runtime that demands more durable heads capable of extended operation. Manufacturers increasingly design heads specifically for electric trimmer applications.

Smart Technology Integration

Emerging trimmer technologies include sensors that monitor line length and automatically feed new line as needed. These systems eliminate the need for bump feeding while optimizing line consumption.

Connected devices may eventually provide maintenance reminders and performance optimization based on usage patterns and cutting conditions. Smart heads could adjust feeding rates automatically for different vegetation types.

Material Innovations

Advanced polymer materials offer improved impact resistance and durability while reducing weight. New formulations resist UV degradation and maintain flexibility across wider temperature ranges.

Biodegradable cutting lines and head components address environmental concerns while maintaining performance standards. These materials offer disposal advantages without compromising cutting effectiveness.

Making the Right Choice

Assessing Your Needs

Consider your trimming frequency and typical vegetation types when selecting a head. Occasional users with light grass trimming needs differ significantly from professional landscapers tackling diverse cutting challenges daily.

Evaluate your current trimmer’s capabilities and limitations. High-performance heads may overwhelm older or smaller engines, while basic heads might not utilize powerful equipment effectively.

Budget considerations should balance initial cost against long-term value. Premium heads often justify higher prices through durability and time savings, while budget options suit light-duty applications.

Brand Loyalty vs. Universal Options

Brand-specific heads typically offer optimal performance and fit for corresponding equipment. However, universal heads provide flexibility for users with multiple trimmer brands or uncertain compatibility requirements.

Consider parts availability and local dealer support when choosing between genuine and aftermarket options. Rural users particularly benefit from components available through multiple retail channels.

Professional vs. Homeowner Applications

Professional users prioritize durability, efficiency, and minimal downtime over initial cost. Features like speed feeding and automatic line advancement pay for themselves through increased productivity.

Homeowners often find the best value in mid-range options that provide convenient features without premium pricing. Weekend warriors benefit from professional-style features at accessible prices.

Conclusion

Selecting the right trimmer head transforms routine yard maintenance from a chore into an efficient, satisfying task. The five heads reviewed here represent the best options across different categories, from premium professional-grade components to budget-friendly universal alternatives.

The Echo 99944200907b New Genuine Speed Feed 400 Head emerges as our top choice for users prioritizing absolute performance and reliability. Its innovative loading system, automatic line feeding, and exceptional durability justify the premium price for serious users.

Budget-conscious homeowners will appreciate the MaxPower 3317233 PivoTrim Universal Replacement Head for its versatility and solid performance across multiple trimmer brands. This head proves that universal compatibility doesn’t require sacrificing quality or reliability.

The Weed Warrior Autowinder II introduces innovative technology that eliminates line-winding frustration while maintaining competitive pricing. Its automatic winding system appeals to users seeking convenience without premium costs.

Aftermarket alternatives like the Hipa Speed Feed 400 provide excellent value for Echo trimmer owners wanting speed feed convenience without genuine part pricing. These heads demonstrate that quality aftermarket options can deliver professional results.

Whether you’re maintaining a small suburban lawn or managing extensive commercial properties, the right trimmer head makes all the difference. Invest in quality components that match your needs and usage patterns, then maintain them properly for years of reliable service. Your trimmer—and your back—will thank you for choosing wisely.