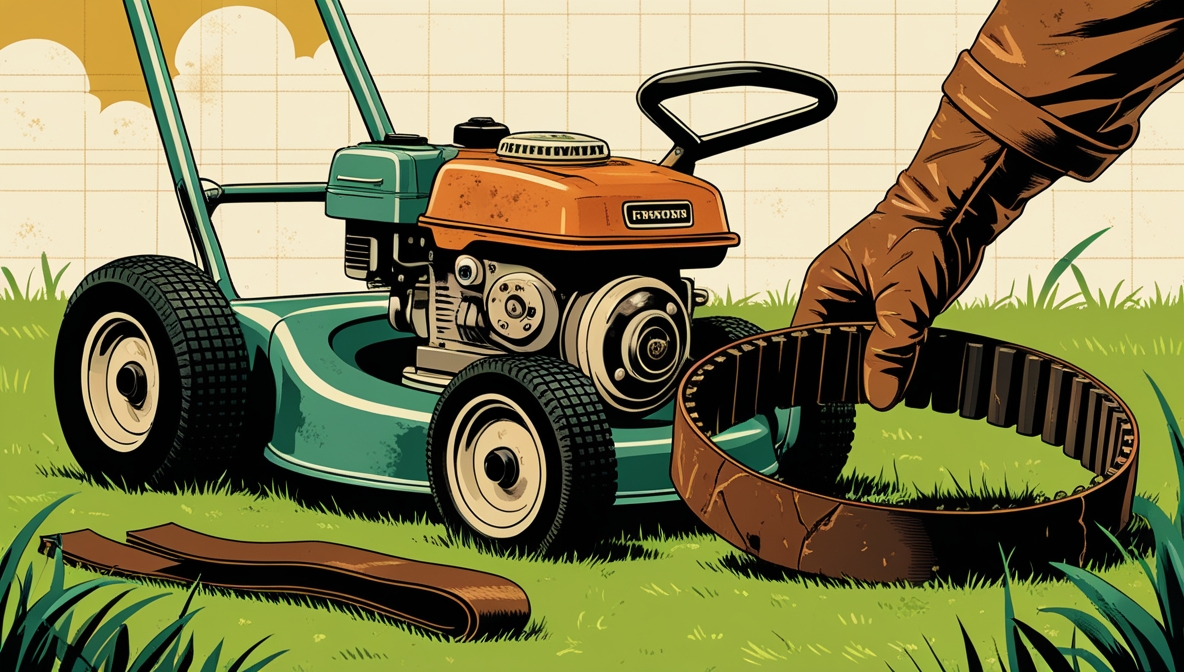

Maintaining your lawn mower is crucial for ensuring its longevity and efficient performance. One of the most common maintenance tasks involves replacing the drive belt, a vital component that transfers power from the engine to the cutting blades. This beginner’s guide will walk you through the process of replacing a lawn mower belt, step-by-step, making the task manageable even for those with limited mechanical experience. Remember to always consult your lawn mower’s owner’s manual for specific instructions and diagrams relevant to your model. Safety should be your top priority throughout this process.

Contents

- Assessing Your Lawn Mower’s Needs

- Identifying the Correct Replacement Belt

- Gathering Necessary Tools & Materials

- Disconnecting the Old Drive Belt

- Accessing the Belt’s Routing System

- Carefully Removing the Worn Belt

- Positioning the New Replacement Belt

- Re-routing the Belt Through the System

- Reconnecting the Drive System Components

Assessing Your Lawn Mower’s Needs

Before you even think about ordering a new belt, carefully examine your lawnmower. Is the engine running but the blades aren’t turning? This is a strong indication that the belt has snapped or is severely worn. Listen for unusual squealing or slipping noises while the engine is running. These sounds often precede complete belt failure and signify excessive wear or misalignment. A visual inspection is also key; look for cracks, fraying, or significant stretching in the existing belt. A belt that’s visibly damaged needs replacing immediately to prevent further damage to your mower. Neglecting a worn belt can lead to engine strain and costly repairs down the line.

Furthermore, consider the overall condition of your lawnmower. While replacing the belt is a relatively straightforward task, it’s a good opportunity to inspect other components. Check the condition of the pulleys and ensure they are free from damage or excessive wear. Inspect the blade for sharpness and balance. A well-maintained lawnmower will operate more efficiently and safely. If you find other issues, address them concurrently to maximize your maintenance efforts. Taking this preventative approach can save you time and money in the long run.

Identifying the Correct Replacement Belt

Once you’ve determined that you need a new belt, the next crucial step is to identify the correct replacement. Never guess; using the wrong belt can lead to performance issues or even damage your mower. The easiest way to find the right belt is to check your owner’s manual. The manual will list the exact part number for your mower’s belt, making the process straightforward. Alternatively, you can look for a sticker or label on the mower itself, often located near the engine or under the deck, that provides the model and serial number.

If you can’t locate the information in your manual or on the mower, take a picture of the old belt and visit a local hardware store or lawn equipment dealer. The staff can help you identify the correct replacement based on the belt’s dimensions and construction. Online retailers also offer search tools where you can input your mower’s model number to find the correct belt. Ensure you double-check the specifications to guarantee a perfect fit. Using an incorrect belt can lead to slippage, premature wear, and ultimately, mower failure.

Gathering Necessary Tools & Materials

Before you begin the replacement process, gather all the necessary tools and materials. This will streamline the process and prevent interruptions. First and foremost, you’ll need the new replacement belt, identified as described in the previous section. You’ll also need a set of screwdrivers (Phillips and flathead), possibly a wrench or socket set depending on your mower’s design, and a pair of pliers. Having gloves on hand is recommended to protect your hands from dirt and grime.

Additionally, consider having a rag or shop towel handy to clean up any spills or debris. A flashlight can be helpful for illuminating hard-to-see areas, especially if you’re working in low-light conditions. Some mowers might require the removal of the spark plug wire to prevent accidental starting. If this is the case, you’ll need a spark plug wrench. Having all the necessary tools ready beforehand will make the process much smoother and less frustrating. Organize your workspace to ensure easy access to everything you need.

Disconnecting the Old Drive Belt

With the tools assembled, the next step is to safely disconnect the old drive belt. Begin by turning off the lawn mower and ensuring it’s completely unplugged from any power source. Safety is paramount; never attempt to work on a running machine. Locate the belt’s connection points. These are typically pulleys connected to the engine and the blade assembly. Depending on your mower’s design, you might need to remove some screws or access panels to gain better access.

Once you have visual access to the belt, carefully inspect its routing. Take note of how it runs around the pulleys; this will be crucial when installing the new belt. You might need to slightly loosen or remove some components to create enough slack to release the belt from the pulleys. Use your hands or pliers to gently release the belt from each pulley, being careful not to damage the pulleys or the belt itself. Work methodically and slowly to avoid any accidental damage. Once the belt is completely disconnected, carefully set it aside.

Accessing the Belt’s Routing System

After disconnecting the old belt, you may need to access the belt’s routing system more thoroughly. This often involves removing additional components to gain a clear view of the pulleys and the path the belt follows. Consult your owner’s manual for specific instructions on accessing the belt system for your model. Some mowers have easily removable panels or covers, while others may require more extensive disassembly.

Depending on your mower’s design, you might need to remove the mower deck, which houses the blades. This usually involves removing several screws or bolts. Remember to support the deck as you remove it to avoid injury. Once the deck is removed, you will have a much clearer view of the entire belt routing system, allowing for easier installation of the new belt. Take your time and work carefully to avoid damaging any components during this process. Again, photographs can be incredibly helpful in remembering the order of removal and reassembly.

Carefully Removing the Worn Belt

With the belt routing system accessible, carefully remove the worn belt. If the belt is broken, this step might be straightforward. If it’s merely worn but still intact, you might need to carefully maneuver it off the pulleys. Avoid pulling too hard, as this could damage the pulleys. Once the belt is removed, inspect it closely to identify any signs of excessive wear or damage. This can help you understand the cause of the failure and prevent similar issues in the future.

Before discarding the old belt, take a moment to examine it closely. Look for any obvious signs of wear, such as cracks, fraying, or excessive stretching. Note the direction of the belt’s rotation, as this is crucial for installing the new belt correctly. Take a photograph of the old belt in its position, noting the path it takes around each pulley. This will serve as a valuable reference point when installing the new belt. Proper documentation will prevent installation errors and potential problems.

Positioning the New Replacement Belt

With the old belt removed, it’s time to install the new one. Begin by carefully positioning the new belt around the largest pulley, typically the one connected to the engine. Ensure the belt is seated correctly on the pulley groove. If the belt is too tight or too loose, you might need to adjust the tensioner mechanism. Refer to your owner’s manual for the correct tensioning procedure. Incorrect tension can lead to premature belt wear or slippage.

Remember the path the old belt followed, as noted in the previous steps. Carefully align the new belt with the pulleys, ensuring it sits correctly in each groove. Avoid forcing the belt onto the pulleys; it should fit snugly without excessive effort. If you encounter resistance, double-check the belt’s alignment and ensure you haven’t missed a pulley. Take your time and work methodically to avoid making mistakes. Correct positioning is critical for proper function and longevity of the new belt.

Re-routing the Belt Through the System

Now, carefully route the new belt through the system, following the path of the old belt. This might require some maneuvering, especially in tight spaces. Work slowly and deliberately, ensuring the belt is correctly seated in all the pulley grooves. If you encounter any difficulty, refer to your owner’s manual or the photographs you took earlier. Double-check the belt’s path multiple times to ensure it’s correctly aligned.

As you re-route the belt, make sure that it’s not twisted or kinked. A twisted belt will not only reduce its lifespan but could also cause damage to the pulleys. If you notice any resistance or difficulty, stop and re-evaluate the belt’s path. It’s better to take your time and ensure correct alignment than to rush and risk damage. Once the belt is completely routed, you can proceed to reconnect the drive system components. Remember to take your time and be patient during this stage.

Reconnecting the Drive System Components

Once the new belt is correctly routed, reconnect all the components you removed earlier. This might involve reattaching the mower deck, replacing panels, or tightening screws. Ensure all components are securely fastened to prevent any movement or vibration during operation. Double-check all connections before proceeding to the next step. Loose connections can lead to belt slippage or damage.

After reconnecting everything, take a moment to visually inspect your work. Ensure that all components are securely fastened and that the belt is correctly aligned and tensioned. If you’re unsure about any aspect of the reassembly, consult your owner’s manual. It’s better to take extra time and ensure everything is correctly reassembled than to rush and risk damaging your mower. A careful and thorough reassembly will ensure